Semiconductor manufacturing is a sequence of ultra-precise processes where even a single particle can lead to critical device failure. The water used in these processes is not ordinary water, but Ultrapure Water (UPW), managed to the level of an advanced engineered material.

In everyday water, ions such as sodium (Na⁺), calcium (Ca²⁺), and chloride (Cl⁻) are dissolved. These ions exhibit electrical conductivity, which can cause circuit damage or yield loss. Certain ions can penetrate the gate oxide layer of semiconductor devices, destabilizing their electrical characteristics, and over time, residual ions may form particles on the wafer surface.

Moreover, high-purity process chemicals used in etching or developing steps can undergo unwanted reactions in the presence of ions in water, making it impossible to rely on conventional water or standard purified water. For this reason, the semiconductor industry exclusively employs UPW, with impurities reduced to nearly zero.

KoMiCo applies this ultrapure water technology to its cleaning and coating processes for semiconductor equipment parts, thereby ensuring the highest level of cleanliness and contamination control.

■ What is Ultrapure Water?

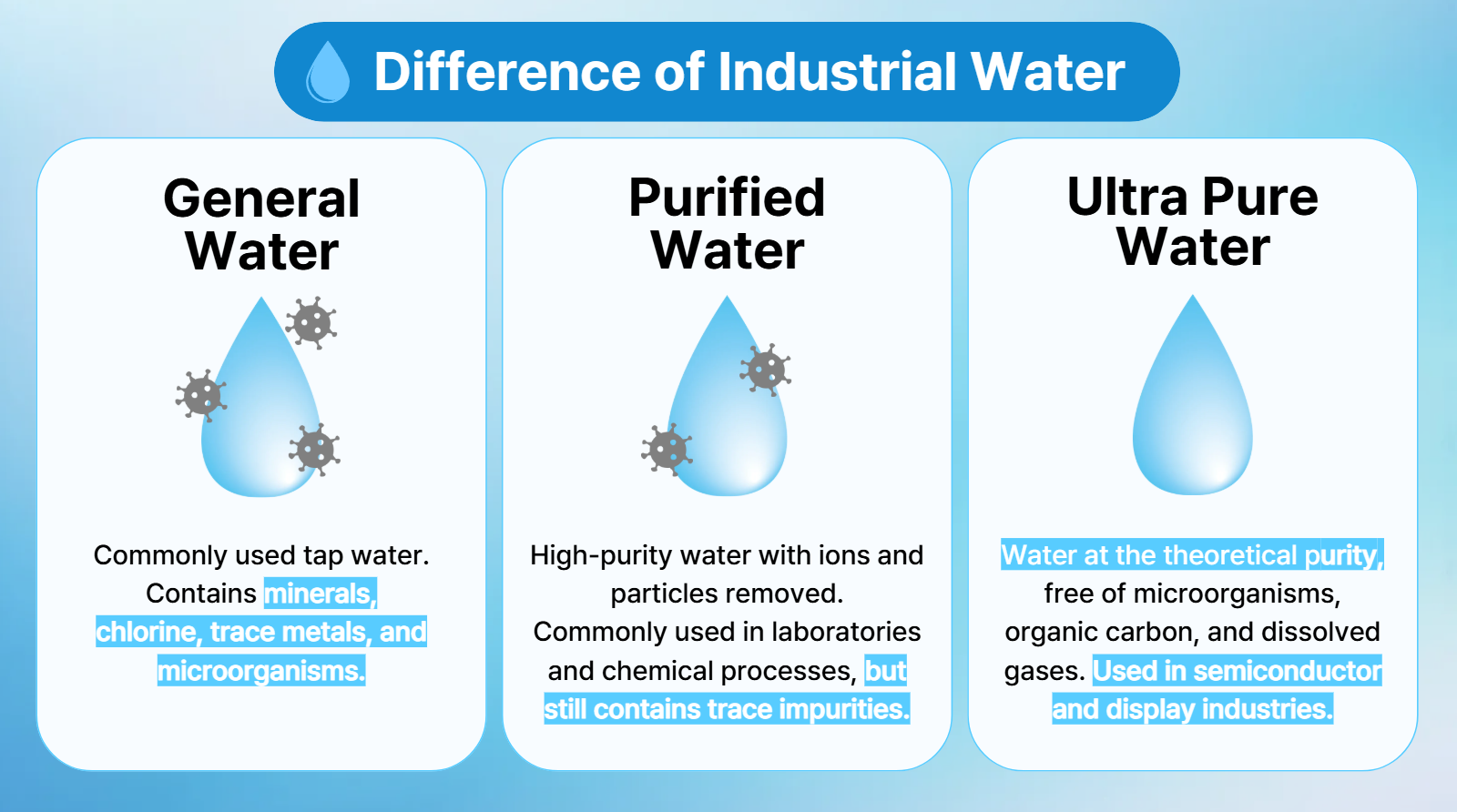

Ultrapure Water (UPW) is water in which nearly all impurities other than H₂O are completely removed.

In the semiconductor industry, UPW is more than 10⁶ times purer than conventional purified water, with ions, microorganisms, organics, particles, and dissolved gases all eliminated.

Ultrapure Water Management Parameters and Standards for Semiconductor Applications

| Category | Control Standard |

| Electrical Resistivity | ≥ 18.2 MΩ·cm (25 ℃) |

| Conductivity | ≤ 0.055 μS/cm |

| TOC (Total Organic Carbon) | < 1 ppb |

| Particles | ≥ 0.05 μm, ≤ 1 particle/mL |

| Microorganisms | < 1 CFU/100 mL |

| Dissolved Oxygen | Tens of ppb or lower |

UPW is a critical process material in semiconductor manufacturing, directly impacting product yield, reliability, and equipment durability. It prevents contamination on wafers and tools while also inhibiting corrosion of metallic components. Therefore, UPW is also widely used in display, secondary battery, and precision robotics industries.

Semiconductor parts cleaning with UPW is typically divided into High-Pressure Cleaning and Hot DI Water Cleaning, each operating on different principles and delivering distinct process benefits.

■ High-Pressure Cleaning

This method uses a high-pressure pump to compress UPW and spray it through precision nozzles, physically stripping away contaminants. Pressures of 100–150 kg/cm² are commonly applied, achieving strong cleaning performance without chemicals.

Its primary advantage is the effective removal of firmly adhered films, coating residues, and metallic scale from component surfaces. It ensures high cleaning quality while minimizing substrate damage and offers eco-friendliness by eliminating chemical usage.

■ Hot Water Cleaning

In this method, external heating energizes contaminant molecules, weakening intermolecular bonds and causing the impurities to detach from surfaces. This thermally enhanced process enables effective removal of residues while maintaining substrate integrity.

Hot water cleaning is particularly effective under conditions where contaminants undergo endothermic decomposition. Contaminants such as organic compounds, which can be broken down with relatively low energy, are easily decomposed at the molecular level and removed in high-temperature conditions. In addition, hot ultrapure water reduces surface tension, allowing it to penetrate into micro-gaps more effectively, while achieving high cleaning performance without the use of chemical agents.

This method is especially advantageous for removing residual organics or molecular contaminants that are difficult to strip away, and it is regarded as an environmentally friendly cleaning approach. However, its drawbacks include high energy consumption to maintain elevated temperatures and additional time required for heating.

In this article, we examined the principles and characteristics of hot and high-pressure cleaning technologies using UPW. In the next article, we will explore why cleaning technologies for semiconductor equipment parts are becoming increasingly critical, along with the background and necessity behind this trend.

<About KoMiCo>

KoMiCo, established in 1996, was the first company in Korea to commercialize cleaning and coating services for semiconductor equipment components. With global operations spanning the United States, China, Taiwan, and Singapore, KoMiCo has earned quality certifications from some of the world’s leading semiconductor manufacturers, solidifying its position as a Global No.1 in the industry.

Building on its advanced cleaning and coating technologies, KoMiCo continues to enhance its core business while expanding into the development and supply of key OEM components for semiconductor equipment. Moving forward, the company remains committed to improving customers’ productivity and yield, and aims to become a global leader in the semiconductor component cleaning, coating, and manufacturing industry.

'Business' 카테고리의 다른 글

| [KoMiCo Lab] 반도체 산업의 숨은 핵심 기술, 반도체 장비 부품 세정의 이해 (0) | 2025.09.17 |

|---|---|

| 코미코, SEMICON TAIWAN 2025 참가 (0) | 2025.09.17 |

| [KoMiCo Lab] 초순수를 활용한 Water Cleaning (0) | 2025.09.04 |

| [KoMiCo Lab] CO₂ Blasting Technology Combining Precision and Eco-Friendliness (0) | 2025.08.21 |

| [KoMiCo Lab] 정밀성과 친환경성을 겸비한 CO2 Blasting (0) | 2025.08.21 |