In semiconductor manufacturing, particles are more than just contaminants — they are critical variables that directly impact yield. Especially in etching and deposition processes, where nanoscale patterns are formed, even the smallest contamination can lead to a sharp increase in defect rates, reduced productivity, and decreased profitability.

In response to these demanding conditions, AD Coating (Aerosol Deposition Coating) has emerged as a promising surface treatment technology. AD Coating is particularly recognized for its exceptional ability to suppress particle generation, making it a next-generation coating solution for semiconductor equipment.

In this article, we’ll explore what AD Coating is, how it works, and what technical principles and structural characteristics enable it to effectively control particles in advanced semiconductor processes.

■ What is AD Coating?

AD Coating is a vacuum-based surface treatment technology that uses a unique physical principle to form a dense ceramic film by spraying ultra-fine powder particles at high velocity onto a substrate. This process relies on kinetic energy rather than heat, which means it can be applied to heat-sensitive components without the risk of thermal damage.

The core of AD coating lies in “optimized kinetic energy and momentum.” If the kinetic energy is too low, the coating will not adhere properly to the substrate; if it is too high, it may cause substrate damage or lead to fragmentation. KoMiCo’s AD coating precisely controls the speed and mass of particles, enabling perfect adhesion to the base material while minimizing substrate damage.

AD coating forms a strong internal bond through a mechanism known as the "Hammering Effect," where powder particles collide with the surface of the substrate. During this process, the particles compact tightly, resulting in a porosity close to 0%, Vickers hardness (Hv) exceeding 1,000, and adhesion strength over 10N, ensuring excellent mechanical properties.

| Category | APS Coating | AD Coating |

| Coating Method | Thermal spray coating using high-temperature heat source | Direct powder impact in vacuum environment |

| Process Temperature | Extremely high temperature (several thousand °C) | Room temperature |

| Coating Structure | Porous and non-uniform | Dense and uniform |

| Porosity | 3–5% or higher | 0–0.5% or less |

| Hardness | Average 400–600 Hv | Up to 1,000 Hv or higher |

| Particle Generation Risk | Possible due to porosity and delamination | Minimized by dense surface adhesion structure |

Conventional APS coating, due to its inherently porous structure, is prone to erosion when exposed to plasma for extended periods. This erosion can lead to particle detachment from the surface, resulting in particle contamination issues. In contrast, AD Coating features a highly dense and smooth surface structure, which enables it to maintain stable performance over long durations without fragmentation—making it a key differentiator.

The Key Advantages of AD Coating Are as Follows:

Low Porosity Structure

By suppressing micro-porosity within the coating layer to 0–0.5%, AD Coating minimizes the risk of particle detachment caused by plasma erosion.

Strong Internal Bonding Strength

Through the Hammering Effect generated when ceramic powder particles collide with the surface, the particles form a highly cohesive and dense layer. This robust bonding minimizes particle generation even under external friction or thermal shock.

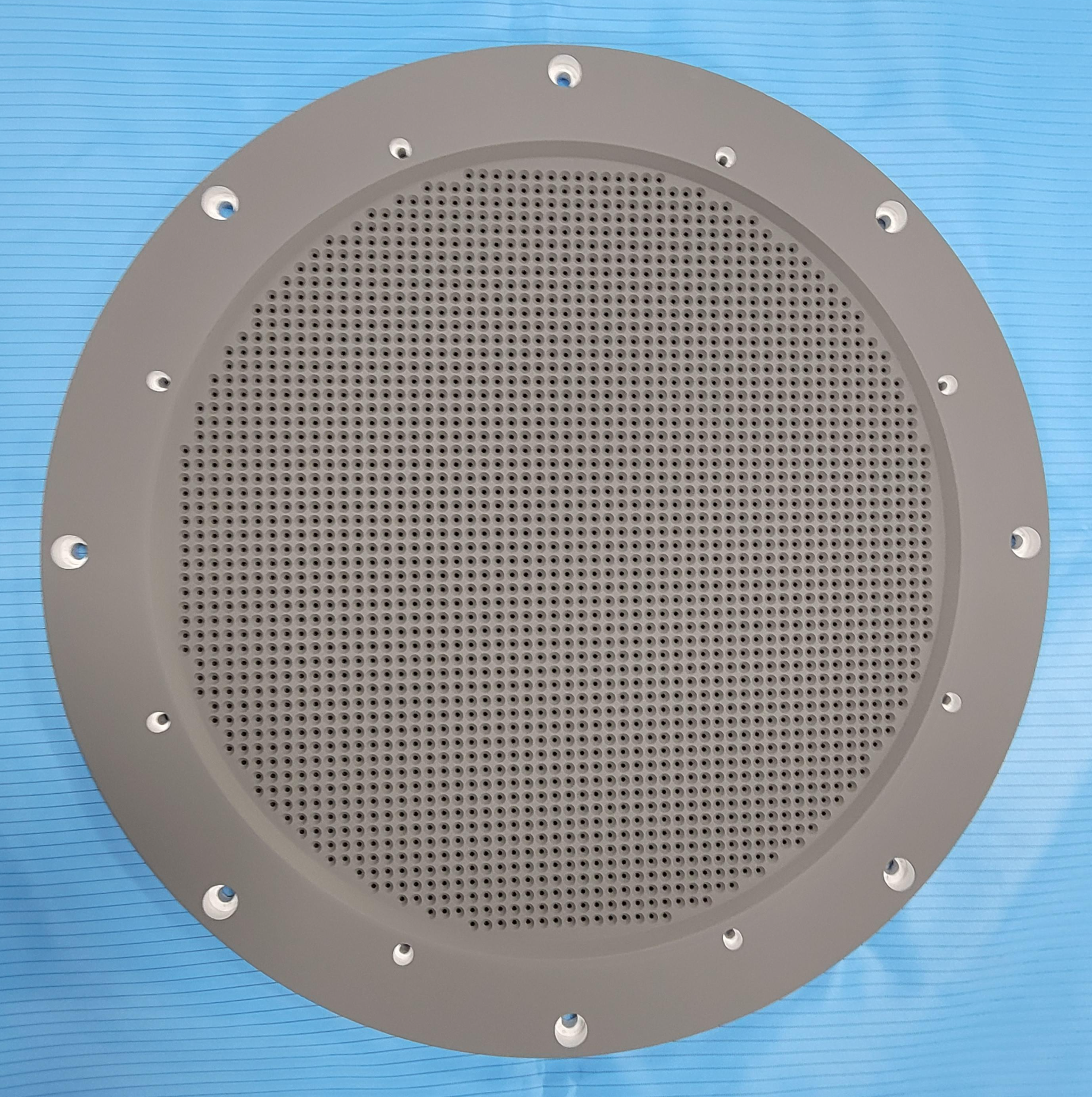

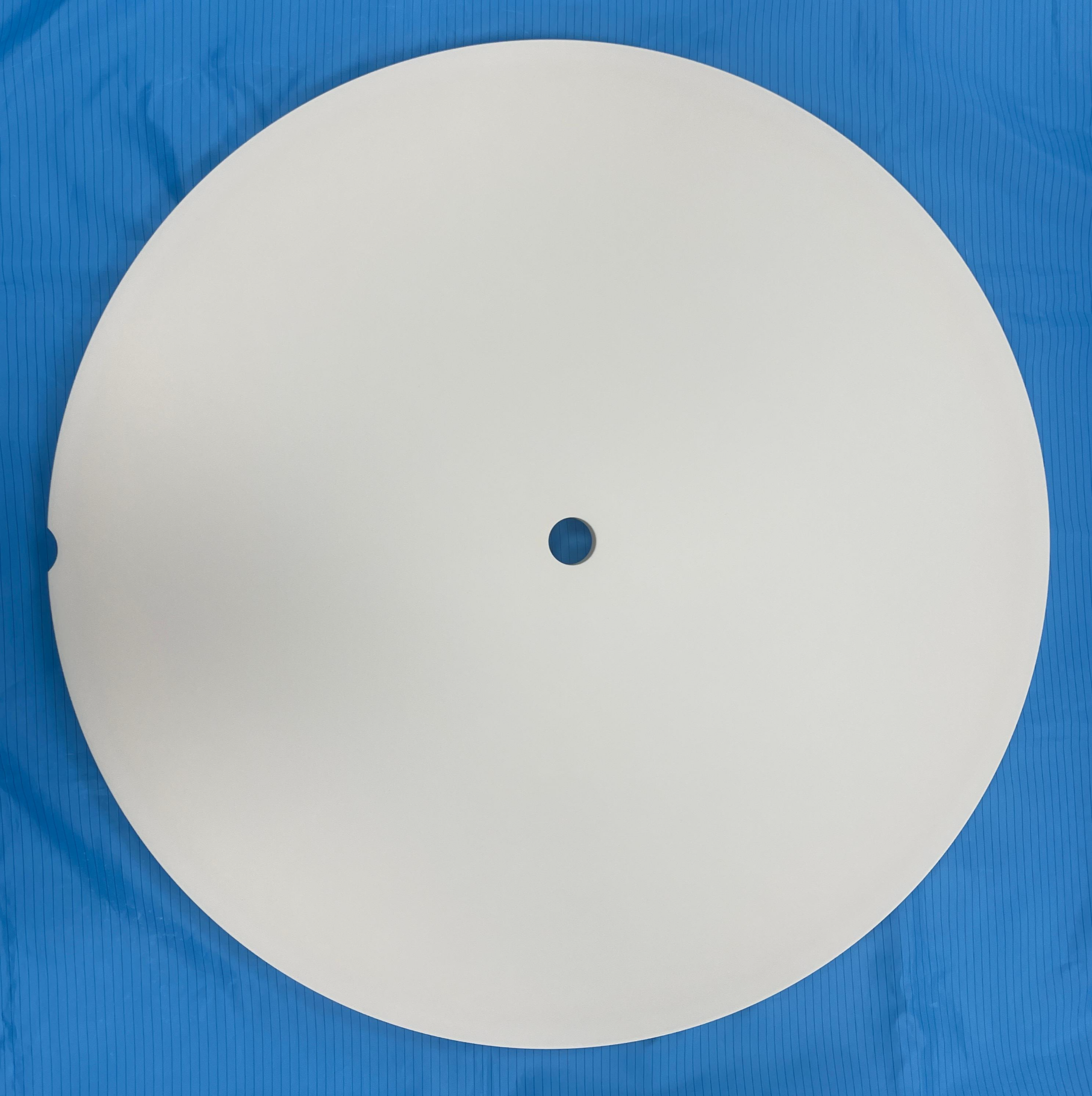

Thanks to these multilayered structural advantages, AD Coating has established itself as an optimal solution for critical parts such as windows and liners in semiconductor etching processes, where particle minimization is essential. It contributes significantly to improving process yield and securing equipment reliability in semiconductor manufacturing.

In the Next Article

We will introduce PVD (Physical Vapor Deposition) Coating, a technology that forms high-performance thin films using a completely different approach from AD Coating. By enabling the formation of high-hardness and highly adherent coatings, PVD Coating enhances the wear resistance and plasma durability of equipment parts, making it a leading solution for boosting both the performance stability and lifetime of semiconductor processes.

Please stay tuned for the next article!

<About KoMiCo>

KoMiCo, established in 1996, was the first company in Korea to commercialize cleaning and coating services for semiconductor equipment components. With global operations spanning the United States, China, Taiwan, and Singapore, KoMiCo has earned quality certifications from some of the world’s leading semiconductor manufacturers, solidifying its position as a Global No.1 in the industry.

Building on its advanced cleaning and coating technologies, KoMiCo continues to enhance its core business while expanding into the development and supply of key OEM components for semiconductor equipment. Moving forward, the company remains committed to improving customers’ productivity and yield, and aims to become a global leader in the semiconductor component cleaning, coating, and manufacturing industry.