The first two keywords when you think of KoMiCo! It’s special coating and fine cleaning.

Among them, the special coating is an essential process that can improve the stability of process conditions and increase the service life by applying it to the surface of the chamber parts of semiconductor equipment. We are developing various types of coating technologies and providing optimized technologies to customers’ processes.

KoMiCo’s special coating technology helps the chamber’s condition to be stable. It improves the service life, production yield rate, and operation rate to help customers reduce their costs.

│ KoMiCo’s main coating technologies

KoMiCo’s main coating technologies can be classified into 5 types.

Each coating technology is classified depending on its purpose of use in detail and responding to the next generation technology with under 10 nm of customers.

KoMiCo special coating - Ceramic Coating

Among the ceramic coating, APS(Y203, FineCera™, SF™) is applied to control particles and make processes stable by giving plasma resistance performance for semiconductor parts.

AD(NOVA™) is used to improve plasma resistance performance and control particle occurrences by densification of surfaces, and PVD(CF™) is used to control particle occurrences, reduce seasoning time, and control CD drift by maximizing plasma resistance performance through hyper-densification and hyper-flattening.

ALD(EGB™) is used for preventing corrosion of parent metal and outgassing, controlling particles and stabilization of processes with atom-unit hyper-densification coated layers.

KoMiCo special coating - Metal Coating

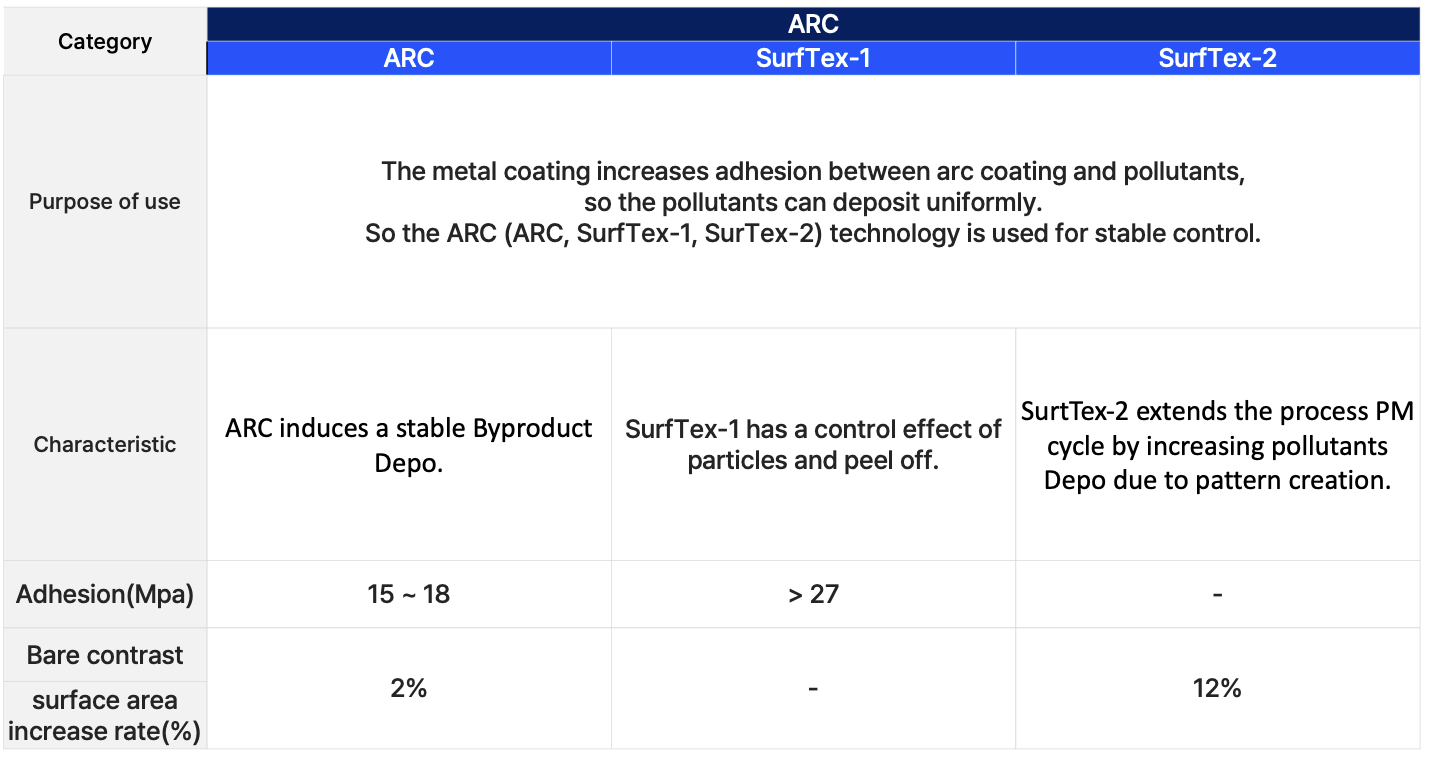

The metal coating increases adhesion between arc coating and pollutants, so the pollutants can deposit uniformly. So the ARC (ARC, SurfTex-1, SurTex-2) technology is used for stable control.

The original ARC induces a stable Byproduct Depo. SurfTex-1 has a control effect of particles and peel off and SurtTex-2 extends the process PM cycle by increasing pollutants Depo due to pattern creation.

KoMiCo special coating – Anodizing

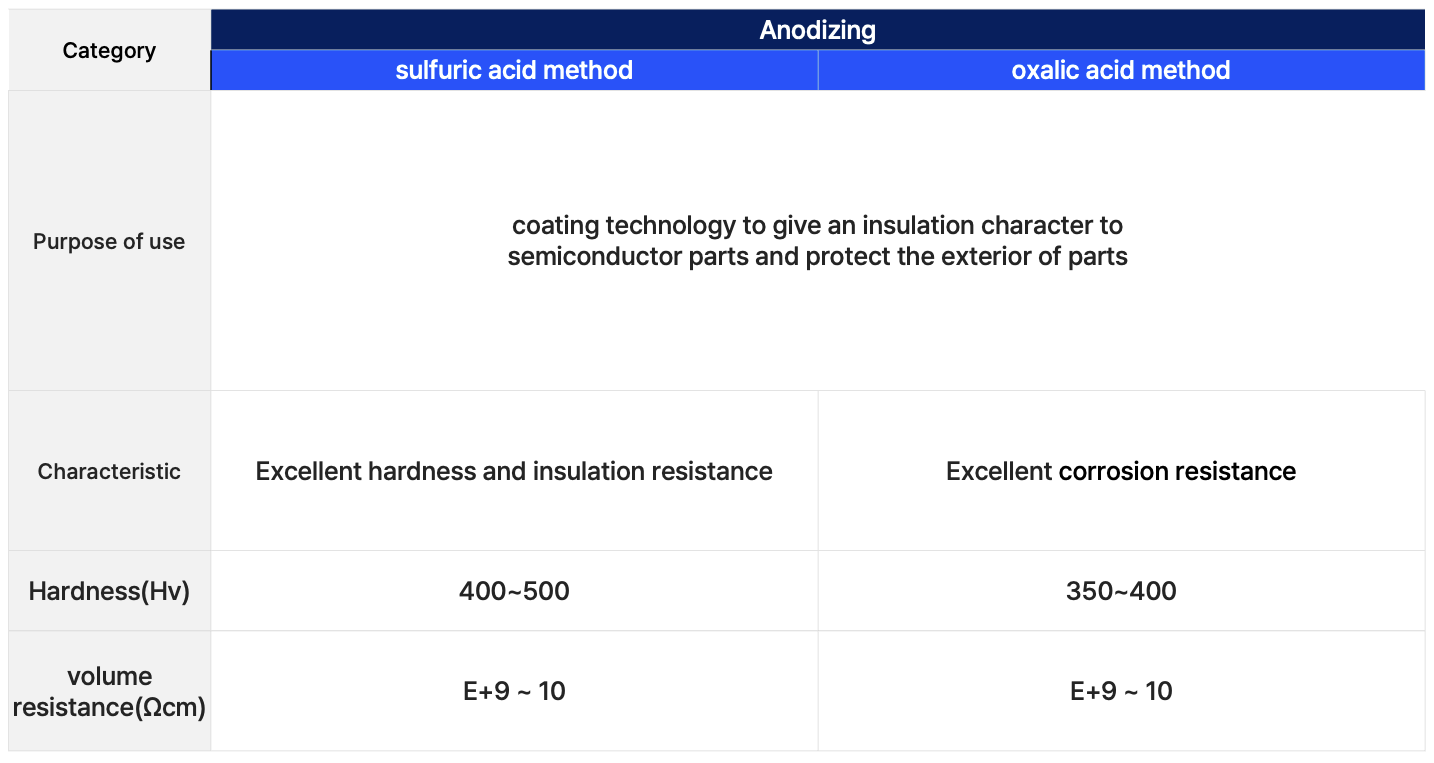

Anodizing is a compound word for Anode and Oxidizing, and coating technology to give an insulation character to semiconductor parts and protect the exterior of parts.

Anodizing can be categorized as a sulfate method which has a hardness of 400 to 500 and superior insulation features and an oxalate method which has a superior corrosion resistance. A technology with an appropriate characteristic is provided depending on a customer process.

Lots of global semiconductor companies from the United States, China, Taiwan, and Singapore are experiencing KoMiCo's special coating technologies.

Extend the service life with our differentiated special coating technology of semiconductors and improve the production yield rate and operation rate.